Outstanding Performance of Drills : Effect of NexGen Edge Preparation

…An AXIS mICRO Tools Perspective

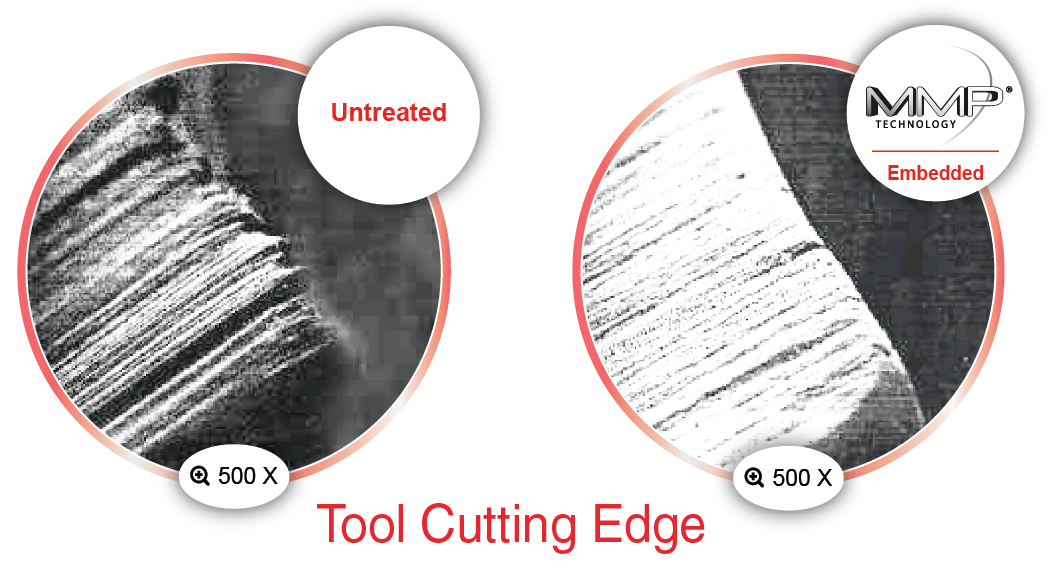

One of the differentiations that high performance tools have is the preparation of their cutting edge. Cutting edge preparation influences the Thermo-Mechanic aspects of the cutting process such as the deformation zone, the temperature distribution in the cutting process, the machining process, the chip formation and its flow, the superficial integrity of the job, resistance to wear and microchipping and tool life.

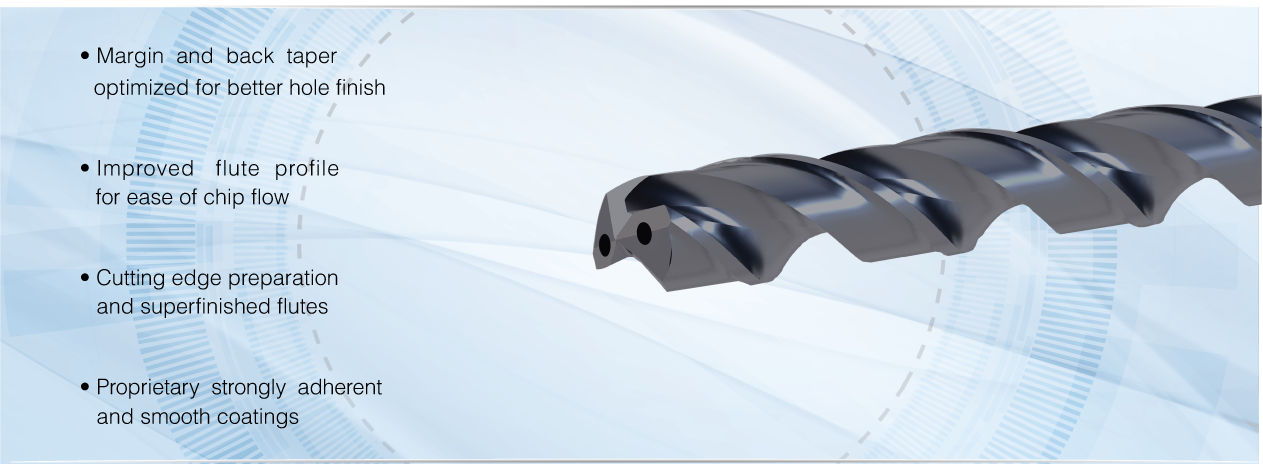

Cutting edge preparation is the process of adapting the surface of the cutting edge for improving the contact zone for machining and the coating process. The cutting-edge preparation could be done by either honing, chamfering or the combination of both to improve the microtopography for efficient and effective cutting action.

When the process is executed properly it increases the strength of the cutting edge and lifetime of the tool, increases coating productivity, minimizes the possibility of built-up-edge formation and enhances surface quality of the job.

AXIS mICRO Tools uses a unique proprietary superfinishing process to stabilize the cutting edges.The process is highly reliable, consistent and repeatable. Application industries benefiting from this process are Aerospace, Medical, mICRO mACHINING, e Mobility, Consumer Electronics, to name a few and the list is increasing.

Here is a case study which brings succinctly the benefits of superfinishing and edge preparation on the performance of AXIS Tools used in a high precision application in Aerospace Industry.

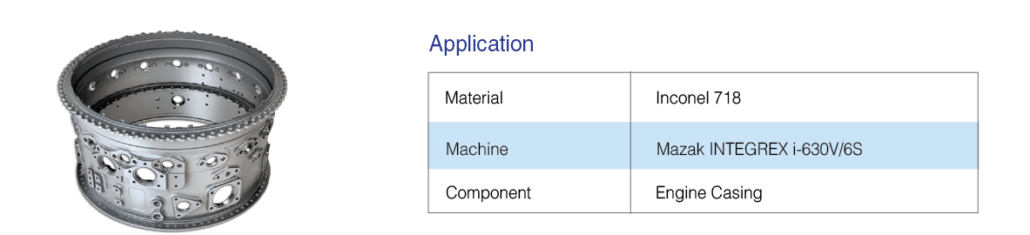

Case Study : Machining of Engine Case

Cases are an integral part of the Aircraft Engine that shield and support the parts required for combustion. Hence, they are made from materials that can withstand rapid changes in temperature and are light weighted as well. Heat Resistant Super Alloys (HRSA) such as Inconel and Nickel Alloys, Titanium and Stainless Steels are the materials of choice in such applications.

Drilling Nickel based super alloy is very challenging due to the material properties, operating conditions – large amount of heat generation and its dissipation – and the high component quality requirements.

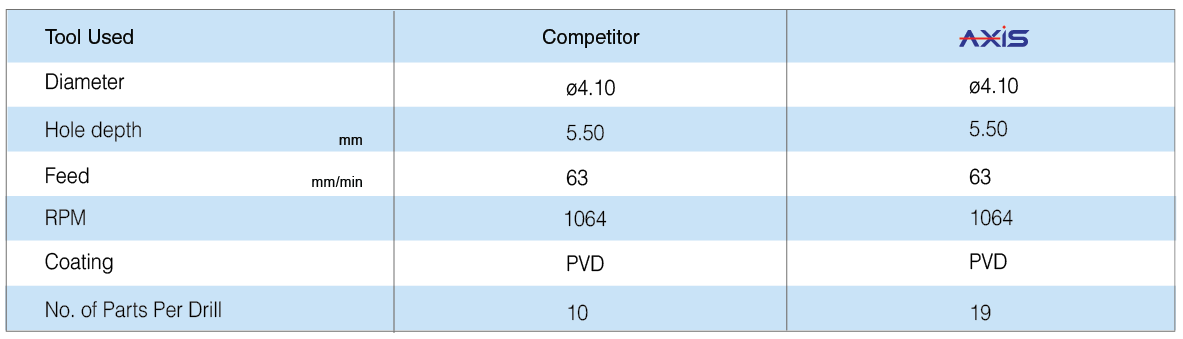

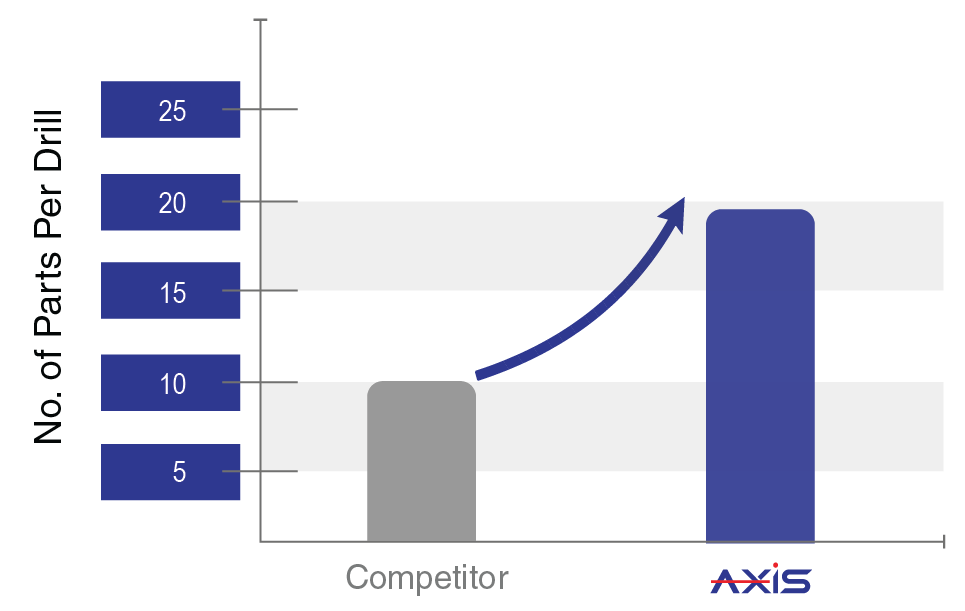

Here is a case of effective design, appropriate edge preparation, and superfinishing – to enhance coating productivity and chip evacuation

( heat dissipation ) – that has resulted in the outstanding performance of the drill.

Enhanced Tool Performance

Results

Distinguishing Features of the Drill in use

Conclusion

Controlled and Consistent micro honing of the cutting edge with a satisfactory texture for subsequent coating process results in strengthening of the cutting edge for improved cutting action, better component quality and extended tool life.

If you are looking for High Precision Super long drilling solutions checkout our…..

The smart LITTLE Coolant Wonder for demanding applications.